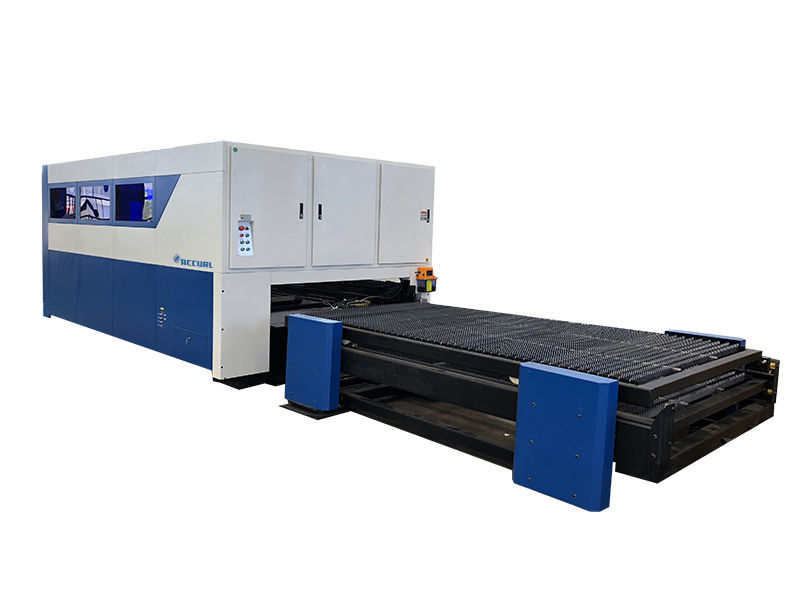

What can we do with Cnc Fiber Laser Cutter 3015 6000w 8000w For Aluminum

1.Application Materials:Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

2.Application Industries: ACCURL Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Agahdariya bingehîn

Teknolojiya Laser: Qutkirina Laser Fusion

Total Weight: 8t

Garantî: 1 Sal

Color: White&Blue

Laser Source Power: 500W,700W,1kw,1.5kw,2kw,3kw,4kw,6kw,8kw

Cutting Ability: 0.1-30mm

Working Size: 1500mmx3000mm / 2000mmx4000mm / 2000mmmx6000mm

Max Cutting Speed: 40m/Min

CNC Control: Yes

Pakêta Transportê: Doza Plywood-a Standard

Specification: Transport by 20/40 Container

Inêkirin: Chinaîn

| Mezinahiya Xebatê | 3000 * 1500mm |

| Fiber Laser Sorce Power | IPG 500w,700w,1kw,1.5kw,2kw,3kw,4kw,6kw,8kw |

| Hêza Machine | ≤14KW |

| X/Y Position Accuracy | ± 0,05 mm |

| X/Y Reposition Accuracy | ± 0,03 mm / m |

| Max Velocity of Movement | 80m / min |

| Weqfa Machine | 8000KG |

| Laser life(hrs) | 100000 |

Avantajên

Laser cutting offers a huge number of advantages to its users:

Laser cutting allows for great control over beam intensity, length and heat output

Laser cutting uses an extremely low level of power consumption, typically around 10Kw as compared to 50Kw used by other processes

Laser cutting can work with a huge range of materials

Laser cutting is a non-contact process, meaning that the laser beam itself never actually touches the material it works with. This reduces heat damage to the surrounding area, which increases productivity by decreasing downtime and repair costs

Laser cutting machines have very low maintenance costs and inexpensive parts for replacement

Laser cutting delivers precise cuts with smooth finishes

Laser cutting can switch quickly between multiple applications and setups, reducing time wastage and the need for multiple machines

With the above advantages, it is easy to see why laser cutting is becoming so widely used.

After-Service&Warranty

1.One year warranty for machine and two years warranty for fiber laser source

2.We will provide the consumable parts at an economic price.

3. 24 hours online service and a high attention, free technical support. (Door to Door service)

4.Machine has been adjusted before delivery, operation disk is included in the delivery.If there is any other questions, pls kindly tell me.

5.We have manual instruction and CD (Guiding Videos) for software Installation, operation and machine's using and maintenance.