A fiber laser is a laser in which the active gain medium is an optical fiber doped with rare-earth elements such as erbium.

The way it generates its beam is distinctly different from that of a Co2 laser which uses resonators.

Fiber lasers are much more ecofriendly than Co2 lasers using typically less than 50% power consumption compared to a Co2 Laser.

They are also more reliable and cut parts up to 6mm thick 30-40% quicker than a Co2 Laser.

Taybetmendiyên makîneya qutkirina fîberê ye

1.Qalîteya tîrêjê ya hêja: Pîvana hûrgelê ya piçûktir û karbidestiya xebata bilind, kalîteya bilind.

2.High cutting speed: cutting speed is more than 20m/min.

3.Rewşa domdar: pejirandina lazerên fîberê yên importa cîhanê ya herî mezin, performansa aram, beşên sereke dikarin bigihîjin 100,000 demjimêran

4.High efficiency for photoelectric conversion : Compare with CO2 laser cutting machine ,fiber laser cutting machine

bandora veguherîna veguherîna wênesaziyê sê caran heye

5.Lew mesrefa: Save enerjiyê û parastina jîngehê.Low xerckirina hêza elektrîkê.

6.Parastina kêm: Veguheztina xeta fiberê, ne hewce ye ku lens nîşan bide, lêçûna lênihêrînê xilas bike;

Operasyonên 7.Easy: veguheztina xeta fiber, ne verastkirina riya optîkî;

Dîroka Teknîkî ya makîneya qutkirina fîberê ye

| Cins | makîneya qutkirina fîberê ye | ||

| Tîpa lazer | Raycus fiber laser | ||

| Navgîna xebatê ya Laser | Mûyik | ||

| Dirêjiya bergê Lazerê | 1064 nm | ||

| Hêza laser | 300w, 500w, 750w, 1000w etc | ||

| Kalîteya tîrêjê | <0.373mrad | ||

| Controlling system 4 axis | Bochu (Made in Shanghai) | ||

| System language | Multi languages | ||

| Serê qehirî | U.S.26 | ||

| Motor | 750W YASKAWA servo (Made in Japan) | ||

| Speed reducer | Delta | ||

| Transmission and guide rails | Transmission way for X Y axis | Rack gear (Made in Germany) | |

| Guide rails for XY axis | Imported HIWIN Square guide rail | ||

| Ball screw for Z axis | THK ball screw (from Japan) | ||

| Mêz | Sawtooth | ||

| Chîleka avê | 1P | ||

| Rotary system | Diameter of rotor | 100mm (can actually up to 150mm) | |

| Length of rotor | according to u request | ||

| Industrial computer | Yan hua | ||

| Rêjeya birrîna bi bandor | 3000* 1500mm | ||

| Formata grafîkî piştgirî kir | Auto cad, Corel draw, PLT, DXF, BMP, AI, DST, DWG, etc | ||

| Table axial positioning accuracy | ≤ ± 0.03 mm / m | ||

| Repeat positioning accuracy table | ≤±0.02mm/m | ||

| Leza birrînê | ≤30m/min | ||

| Mezinahiya kaxezê ya berbiçav | 10 mm (according to laser power ) | ||

| Maximum table load | 1600 KG | ||

| Power Ratings | Three-phase 380V 60Hz | ||

| Erk | 6-20KW | ||

| Total power protection class | IP54 | ||

1 Raycus fiber laser generotor

2 US 26 cutting head

3 Bochu controlling system

4 Japan Omron limit switch

5 Water chiller 1p

5 Germany speed reducer

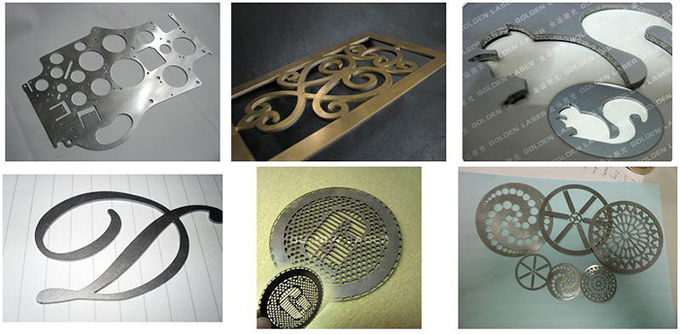

Applications materials of fiber laser cutting machine

Machines Cutting Fiber-Laser bi berfirehî di çêkirinê de Billboard, Reklam, Nîşan, Nîşan, Tîpên Metal, Tîpên LED, Amûrên Metbexê, Nameyên Reklamê, Pêvajoya Pelê Metal, Pêkhatin û Parçeyên Metal, Hesinkerî, Şasî, Pêvajoya Raks û Kabîneyan, Hunerên Metal, Amûrên hunera metal, qutkirina panela asansorê, hardware, perçeyên otomatê, Çarçoveya Glasses, Parçeyên Elektronîkî, Name, û hwd.

Is suitable for stainless steel, mild steel, carbon steel, alloy steel, spring steel, iron, galvanized iron, galvanized sheet, aluminum,

copper, brass, bronze, gold, silver, titanium plates, metal sheets, metal plates, metal tubes and pipes, etc.

Application Industry:

Machines Cutting Fiber-Laser are widely used in manufacture Billboard, Advertising, Signs,

Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal ProcessingMetals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing,

Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Cheap 500W CNC Metal Fiber Laser Cutting Machine for Sale

Cutting ability & Consume

| Mal | Kevir (mm) | Speed(mm/s) | Gas Pressure(MPa) | Xaz | Cutting Height |

| Tev stîl | 0.5 | >200 | 1 | N2 | 0.6 |

| 1 | 90~120 | >1.1 | N2 | 0.6 | |

| 2 | 16~20 | >1.5 | N2 | 0.6 | |

| Steel Carbon | 1 | 120~150 | 1 | O2 | 1 |

| 2 | 35~45 | 0.6~0.8 | O2 | 1 | |

| 3 | 15~18 | 0.3~0.5 | O2 | 1 |

Xizmetên me

1)24 Months for for the whole machine.

2)All the machines will be full tested before shipment.

3)Laser tube 100000 hours' working time.

4)24 hours technical support-- email, telephone or video online.

5)User-friendly English manual for machine using and maintaining.